Responsive Navigation

About FlowCommand

Company Profile

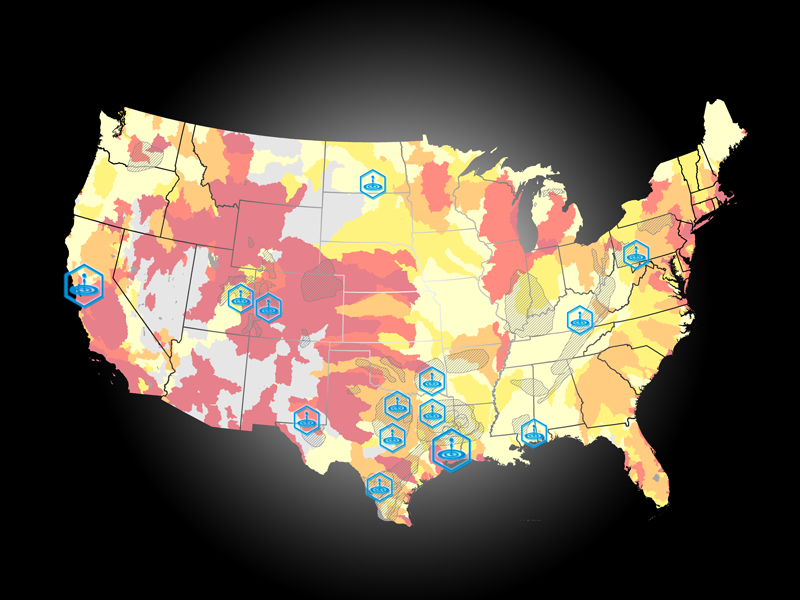

FlowCommand is a full service technology company that provides software and hardware for oil & gas companies. FlowCommand’s mission statement is simple: reduce risks and costs by using expertly architected breakthrough technology. Sensors and software have historically been expensive and difficult to integrate.

FlowCommand is changing that with new technologies that allow customers to easily monitor all their fluids remotely, collect key data, and maximize the impact of that data. The right technology can change the game in the oil patch, and FlowCommand is leading that future

FlowCommand Framework

The oil and gas industry is dominated by antiquated engineering approaches. As an operator, you pay for the equipment, installation, service, and are responsible for sending out field hands to monitor and maintain equipment. We think that this is expensive and clunky—-a perfect representation of what a 1950’s oilfield should looked like.

Though the ‘digital oilfield’ is commonly touted as an industry savior, most equipment today is still designed with antiquated engineering. This renders the equipment too expensive to install, and, therefore, difficult to justify. FlowCommand is changing the digital oilfield with a legacy platform for years to come.

FlowCommand uses a breakthrough system of modular sensor components and server-based software to deliver its data-driven results. Instead of semi-custom SCADA systems, expensive mechanical meters, and messy data transmission and integration, FlowCommand systems are entirely "out of the box". This means that wireless sensors can be installed on any part of an operation instantly.

How can a wireless sensor system be so simple and flexible at the same time? Looking at a particular example:

Here's an example: Operator A has two above ground pits with very uneven bottoms connected by a fastline. This area has very poor celluar service and no access to power. FlowCommand can deliver an advanced monitoring system with 99% accuracy and advanced prescriptions with a simple 8 component system: 2 VoluSense modules, 4 sensor nodes dropped into the pit, and 1 solar and 1 satellite modules for power and connectivity. All modules simply plug and snap together to form a high performance mirco-SCADA system. This keeps costs low, service costs even lower, and features flexible.